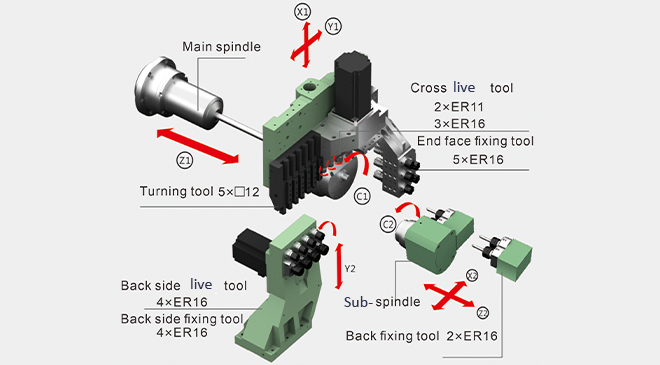

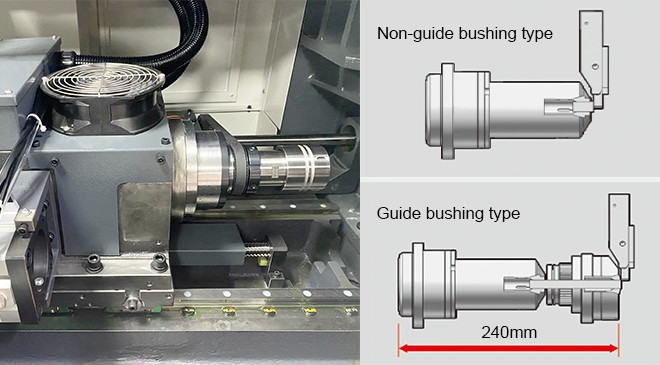

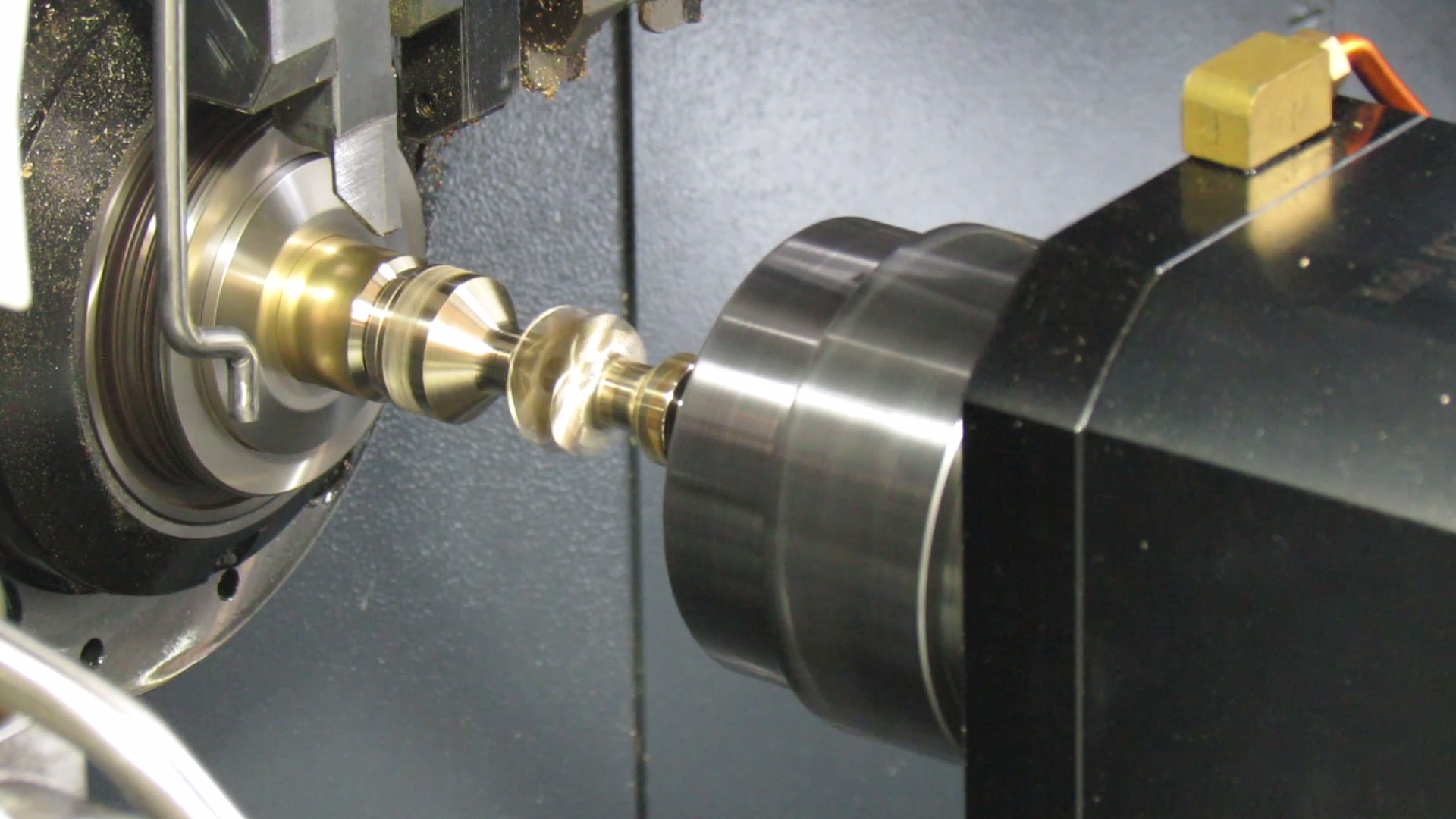

●Machining Max. dia.20/26/32mm, length 240mm workpiece.

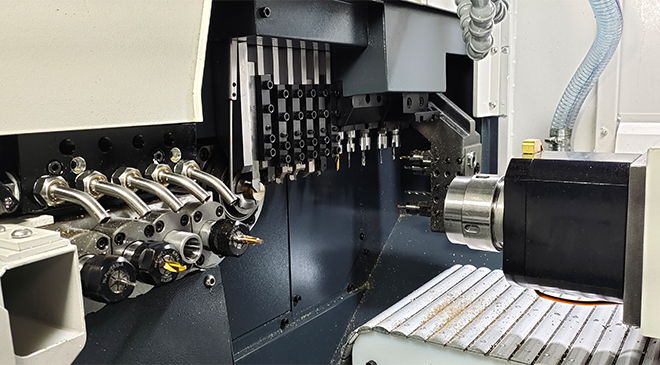

●Main and sub-spindle with two-channel control 5-axis.

●Temperature compensation program improve workpiece precision when cold start.

●Motor built in main spindle, carrier type rotary guide bushing.

●Cut-off tool breakage detector.

En

En Ru

Ru Es

Es Pt

Pt