●The machine can drill and mill with 6/8/12/16 spindles at the same working time(optional taping function).

●Customized fixture for workpiece.

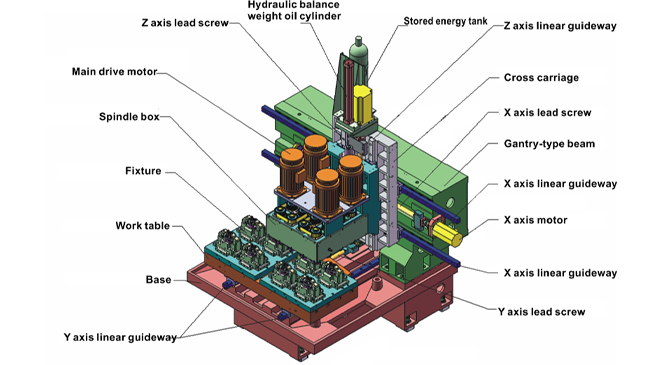

●Gantry-type structure,X axis with large travel.

PRODUCT INTRODUCTION

- FEATURES

- TECHNICAL SPECIFICATION

- CONFIGURATION

- SAMPLE MACHINING

Machine tool structure diagram |

Hydraulic fixture with customized size |

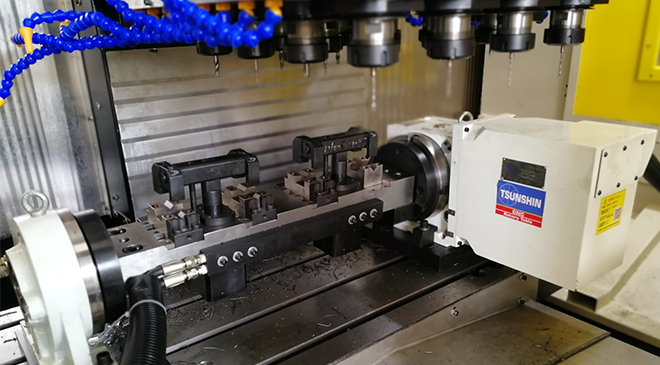

Multi-spindle working together |

CNC rotory table with A axis |

|  |

| Model | AM850F-6 | AM850F-8 | AM850F-12 | AM850F-16 | |||

| Capacity | |||||||

| Worktable size | mm | 560×1260 | 560×1260 | 560×1260 | 560×1260 | ||

| Max. loading worktable | kg | 400 | 400 | 400 | 400 | ||

| T-solt (qty-width*spacing) | mm | 4-18×140 | 4-18×140 | 4-18×140 | 4-18×140 | ||

| Spindle | |||||||

| Spindle nose to table distance | mm | 115-515 | 115-515 | 115-515 | 115-515 | ||

| Spindle center to column guideway distance | mm | 275-695 | 275-695 | 275-695 | 275-695 | ||

| Number of spindle | 6 | 8 | 12 | 16 | |||

| Spindle mount | ER40 | ER40 | ER40 | ER40 | |||

| Drilling diameter | mm | 2—20 | 2—20 | 2—20 | 2—20 | ||

| Power of spindle motor | kW | 6×3.7 | 2×11 | 4×7.5 | 11 | ||

| Max.spindle speed | rpm | 3500 | 3500 | 3500 | 3500 | ||

| Distance of spindle center | mm | 260×240 | 230×230 | 160×240 | 140×140 | ||

| Spindle arrangement | 2×3 | 2×4 | 3×4 | 4×4 | |||

| Travel | |||||||

| X/Y/Z axis positioning accuracy | mm | 0.025/0.022/0.022 | 0.025/0.022/0.022 | 0.025/0.022/0.022 | 0.025/0.022/0.022 | ||

| X/Y/Z axis repeatability positioning accuracy | mm | 0.015/0.012/0.012 | 0.015/0.012/0.012 | 0.015/0.012/0.012 | 0.015/0.012/0.012 | ||

| X/Y/Z axis travel | mm | 1000/320/400 | 900/320/400 | 900/320/400 | 1000/320/400 | ||

| X/Y/Z axis rapid feed | m/min | 16/16/8 | 16/16/8 | 16/16/8 | 16/16/8 | ||

| Other | |||||||

| Weight | kg | 5200 | 5700 | 6150 | 5500 | ||

| Machine size(L×W×H) | mm | 3470×2250×2400 | 3470×2250×2400 | 3470×2250×2400 | 3470×2250×2400 | ||

| Model | AM850F-6 | AM850F-8 | AM850F-12 | AM850F-16 | |||

| Capacity | |||||||

| Worktable size | mm | 560×1260 | 560×1260 | 560×1260 | 560×1260 | ||

| Max. loading worktable | kg | 400 | 400 | 400 | 400 | ||

| T-solt (qty-width*spacing) | mm | 4-18×140 | 4-18×140 | 4-18×140 | 4-18×140 | ||

| Spindle | |||||||

| Spindle nose to table distance | mm | 115-515 | 115-515 | 115-515 | 115-515 | ||

| Spindle center to column guideway distance | mm | 275-695 | 275-695 | 275-695 | 275-695 | ||

| Number of spindle | 6 | 8 | 12 | 16 | |||

| Spindle mount | ER40 | ER40 | ER40 | ER40 | |||

| Drilling diameter | mm | 2—20 | 2—20 | 2—20 | 2—20 | ||

| Power of spindle motor | kW | 6×3.7 | 2×11 | 4×7.5 | 11 | ||

| Max.spindle speed | rpm | 3500 | 3500 | 3500 | 3500 | ||

| Distance of spindle center | mm | 260×240 | 230×230 | 160×240 | 140×140 | ||

| Spindle arrangement | 2×3 | 2×4 | 3×4 | 4×4 | |||

| Travel | |||||||

| X/Y/Z axis positioning accuracy | mm | 0.025/0.022/0.022 | 0.025/0.022/0.022 | 0.025/0.022/0.022 | 0.025/0.022/0.022 | ||

| X/Y/Z axis repeatability positioning accuracy | mm | 0.015/0.012/0.012 | 0.015/0.012/0.012 | 0.015/0.012/0.012 | 0.015/0.012/0.012 | ||

| X/Y/Z axis travel | mm | 1000/320/400 | 900/320/400 | 900/320/400 | 1000/320/400 | ||

| X/Y/Z axis rapid feed | m/min | 16/16/8 | 16/16/8 | 16/16/8 | 16/16/8 | ||

| Other | |||||||

| Weight | kg | 5200 | 5700 | 6150 | 5500 | ||

| Machine size(L×W×H) | mm | 3470×2250×2400 | 3470×2250×2400 | 3470×2250×2400 | 3470×2250×2400 | ||

STANDARD CONFIGURATION:

GSK218 control system

Automatic lubrication system

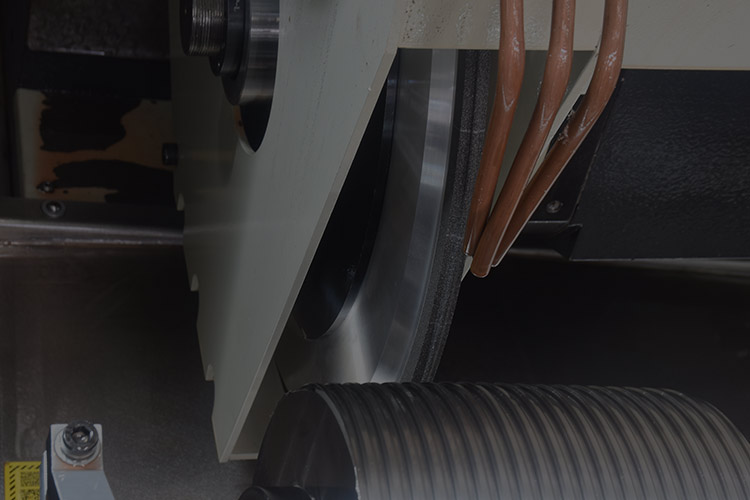

Cooling system

Cabinet air condition

Automatic chip cleaner

OPTIONAL CONFIGURATION:

SYNTEC EZ4 control system

FANUC 0i-mate MD control system

Siemens 808D control system

Tapping device

Automatic fixture

Servo type spindle motor

GSK218 control system

Automatic lubrication system

Cooling system

Cabinet air condition

Automatic chip cleaner

OPTIONAL CONFIGURATION:

SYNTEC EZ4 control system

FANUC 0i-mate MD control system

Siemens 808D control system

Tapping device

Automatic fixture

Servo type spindle motor

En

En Ru

Ru Es

Es Pt

Pt