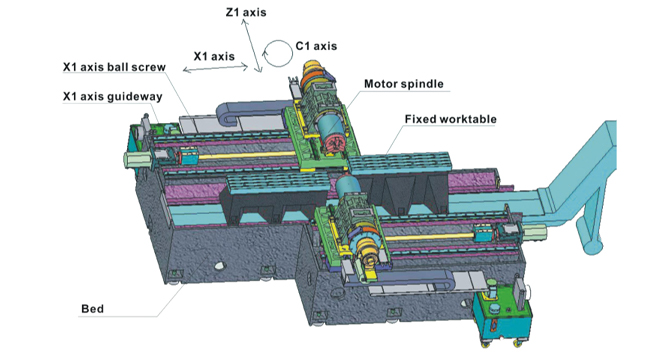

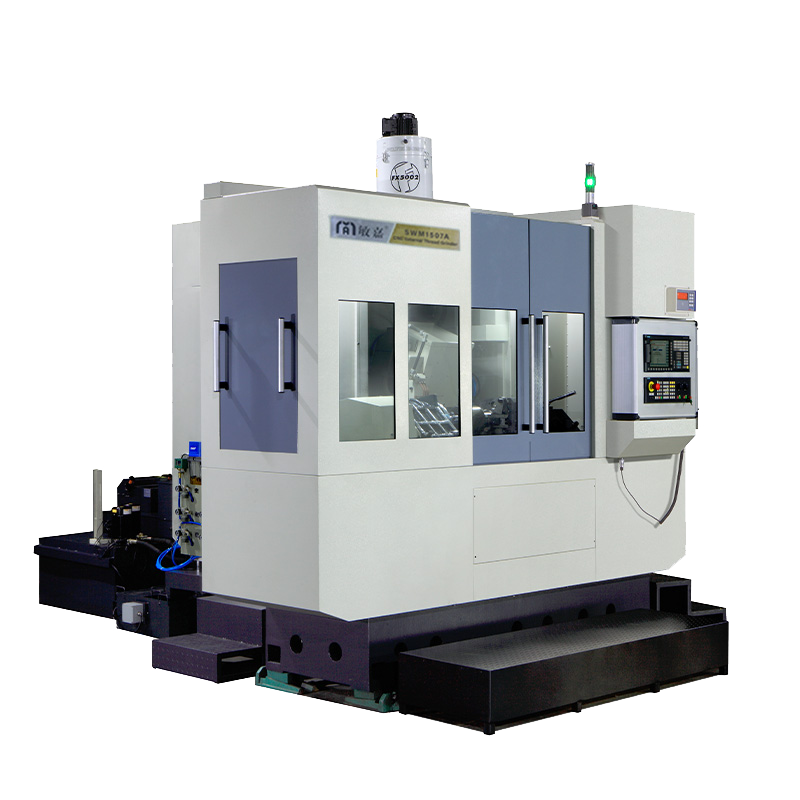

●High rigidity of cast iron bed,the spindle can move with X,Z axis.

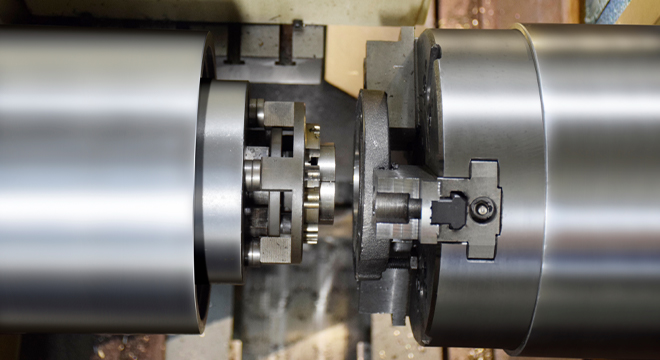

●Two motor spindle,the wrokpiece can butt and butt.

●Two CNC system, 2-spindle work together.

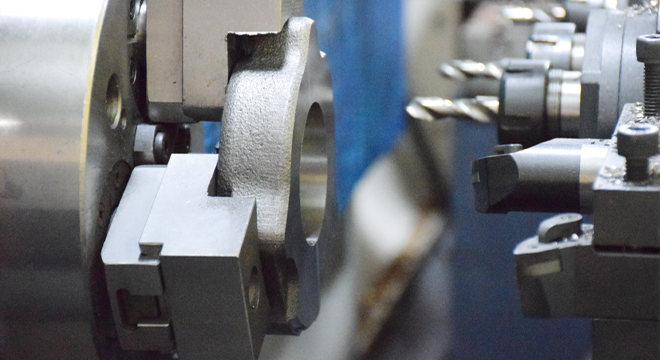

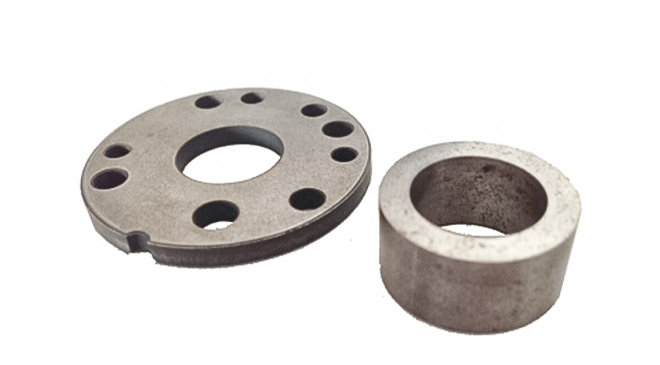

●Suitable for heavy and intermittent cutting processing in auto spare part, compressor for dis type.