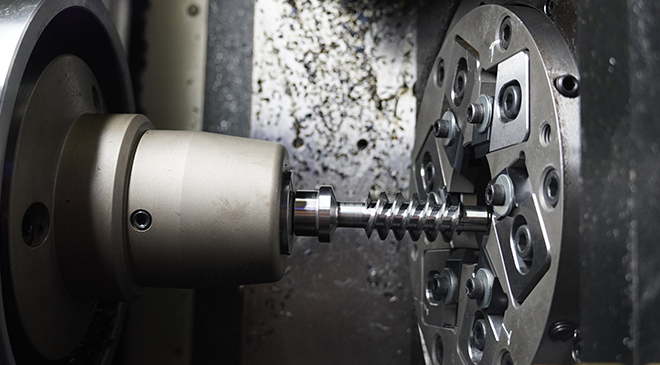

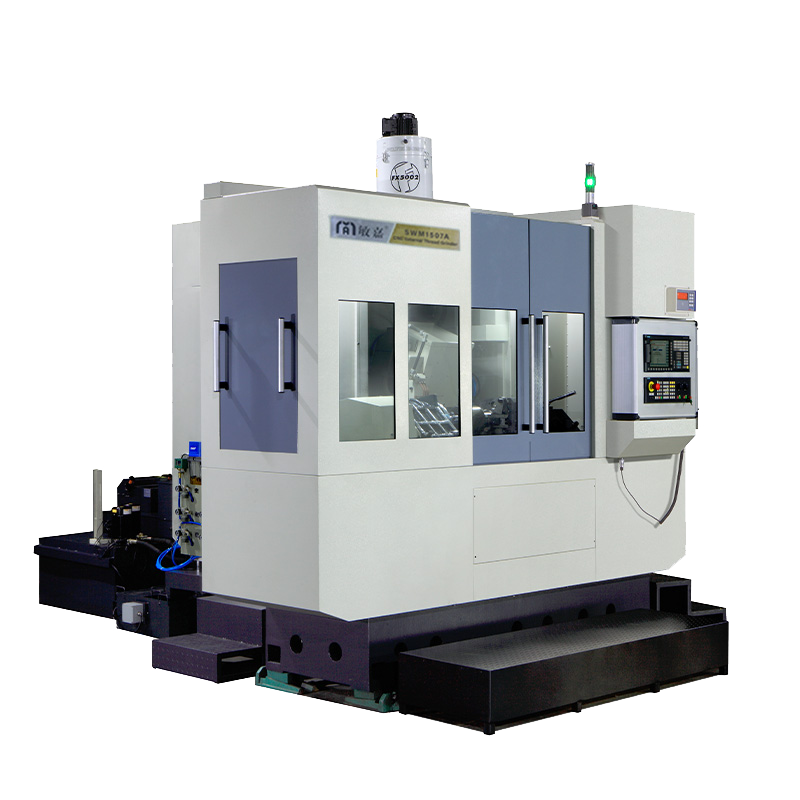

●The machine is professional to mill worm part , it is better efficiency and surface finish for process.

●Workpiece Surface roughness can get Ra 0.4-1.0 μm after milling.

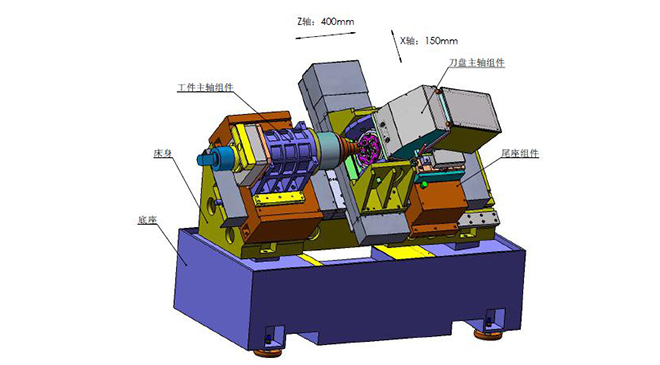

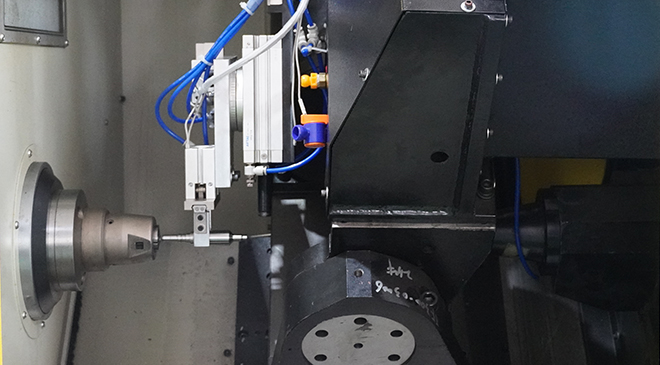

●Turret have high rigidity whirling milling with 5 tools, A axis swinging angle is 0°~18° .

●Siemens motor spindle install round encoder, improve control precision.

●Tool follow drawing to install standard or forming insert for making thread.