Contact us now and start your efficient machining journey!

In today's high-precision manufacturing environment, choosing the right thread-making technology directly impacts product quality, production efficiency, and long-term cost. Two mainstream technologies dominate the field: CNC Thread Grinding and Thread Whirling.

Each offers unique advantages depending on application, material, and accuracy requirements.

What Is Thread Grinding?

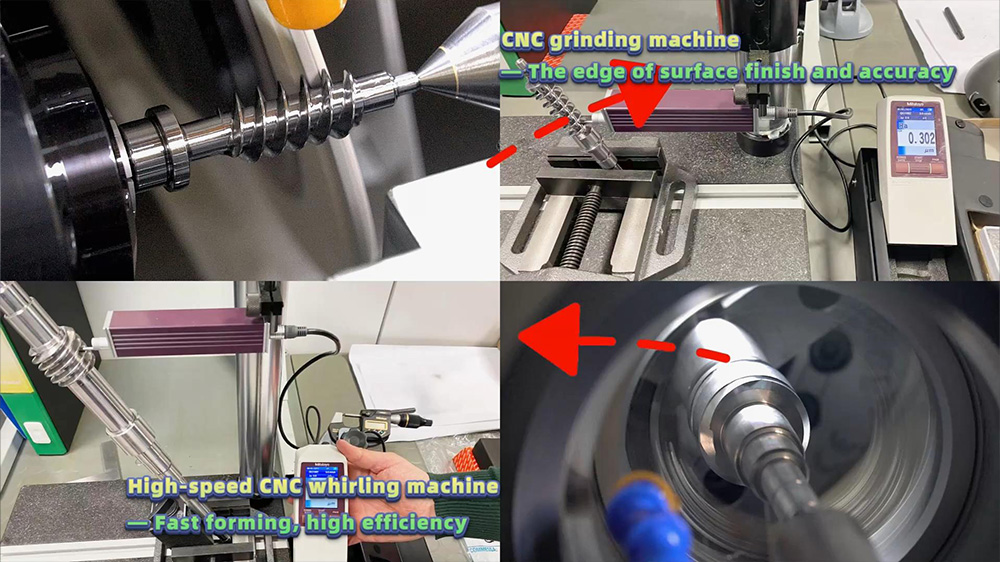

Thread grinding is a finishing process using a CNC precision grinding machine to produce highly accurate threads with superb surface quality.

It is essential for industries where precision is non-negotiable, such as thread gauges, thread rollers, precision toolmaking, and high-accuracy transmission components.

Key Benefits:

●Ultra-high precision (Ra down to 0.3 μm)

●Exceptional surface finish

●Ideal for hardened steel and high-strength alloys

●Suitable for internal and external threads

●Best for tight-tolerance, high-precision components

What Is Thread Whirling?

Thread whirling is a high-speed machining process that uses a multi-tooth cutter ring mounted on a whirling head to generate helical profiles in a single continuous pass.

Unlike conventional turning, the cutter ring rotates at high speed while the workpiece feeds synchronously, enabling fast and stable formation of deep helical grooves.

This technology is particularly effective for worm shafts, miniature worms, and long helical components requiring high efficiency, long engagement lengths, and consistent tooth geometry.

It is widely used in manufacturing precision worms for gearboxes, small transmission systems, automation equipment, and motion-control mechanisms.

Why Thread Whirling Is Ideal for Worm Manufacturing?

Worms have deep, long, and continuous helical profiles that place heavy demands on machining rigidity and chip-removal efficiency.

Thread whirling uniquely meets these requirements through:

●High chip removal rate – The multi-tooth cutter ring removes material quickly, ideal for deep worm profiles.

●Superior stability on slender shafts – The process reduces cutting forces, minimizing deflection.

●Excellent for long lead angles – Whirling naturally handles steep-pitch worms more efficiently than turning.

●Long tool life – Multiple cutting edges distribute load evenly.

●Reduced machining time – Perfect for medium-to-high batch worm production.

For manufacturers producing worms for robotics, automation, or compact gearboxes, thread whirling provides one of the most balanced solutions for speed and consistency.

Side-by-Side Comparison: Precision vs. Speed

1. Accuracy & Surface Finish

Thread Grinding:

●Highest accuracy: ±0.005 mm achievable

●Surface roughness down to Ra 0.3 μm

●Best for precision worms and gauges

Thread Whirling:

●Good accuracy: typically ±0.02–0.05 mm

●Surface finish suitable for industrial worms

●Not a replacement for grinding where ultra-precision is required

2. Production Speed

Thread Grinding:

●Slower due to finishing nature

●Ideal for small to medium batch precision worms

Thread Whirling:

●Extremely high productivity

●Best for long worms and high-volume production

●Great for continuous helical machining

3. Cost Efficiency

Thread Grinding:

●Higher machine cost

●Superior quality for high-value parts

Thread Whirling:

●Lower per-part machining cost

●Efficiency-driven cost advantage

●Strong competitiveness for industrial worm production

4. Applications

Thread Grinding:

●Precision worm gears

●Thread plug & ring gauges

●Thread rollers

●Aerospace threaded components

●High-hardness materials (HRC 60+)

Thread Whirling:

●Worm shafts

●Micro worms for compact transmissions

●Automation equipment drive worms

●General industrial threaded parts

●High-volume helical components

Which One Should You Choose?

If your priority is ultimate precision and surface quality, Thread Grinding is the superior choice.

If your production targets speed, efficiency, and cost-effectiveness, Thread Whirling is the more suitable option.

Many advanced manufacturers combine both technologies:

●Whirling for rough/near-net worm profiles

●Grinding for finishing and high-accuracy requirements

●Balance between precision and throughput

Thread grinding delivers the highest accuracy, while thread whirling provides unmatched efficiency for worm production.

Your choice depends on the precision level, lead angle, batch size, and cost requirement of your target application.

In today’s competitive environment, combining both technologies often produces the best manufacturing performance.

Do you want to know more?

Please click to browse the electronic catalogue